Automotive manufacturers call for the highest levels of precision in parts. A critical aspect is achieving a unblemished sheen on concave edges, which can be tricky with traditional processes. Our pioneering Precision Dished EndAC Polishing Machine targets this need by providing an computerized and rigorous fix. This instrument incorporates advanced tooling and a managed polishing operation to obtain a perfect surface on concave edges, guaranteeing optimal functionality and durability of automotive segments.

- The machine’s programmable controls support for precise changes to the polishing specifications, securing reliability and replicability.

- Its compact architecture boosts workspace utilization while reducing operator burden.

- Fusion with existing manufacturing procedures is straightforward, streamlining production processes.

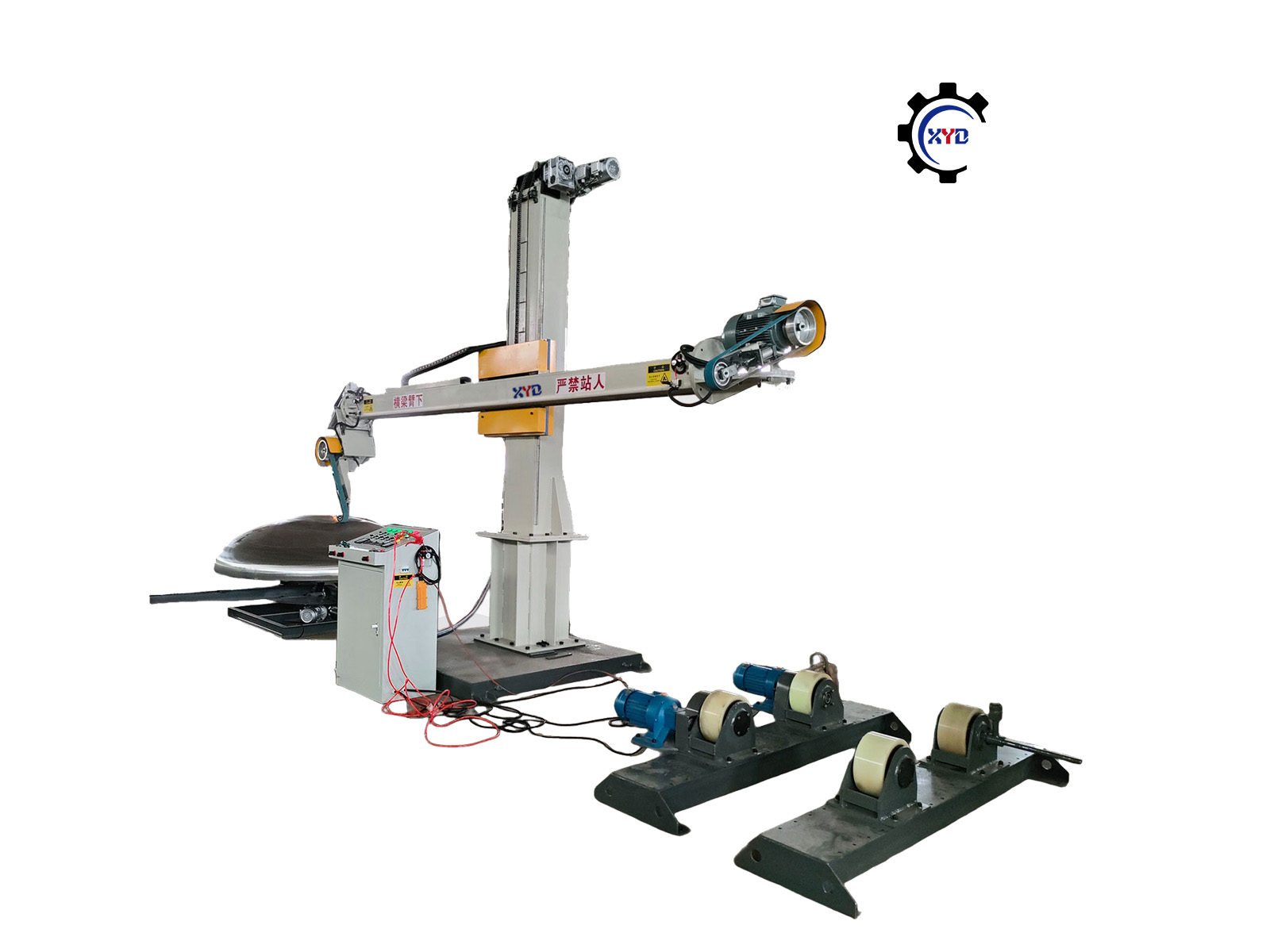

Robust Tank Polishing Machines for Stainless Steel Fabrication

In the domain of stainless steel fabrication, accomplishing a exquisite and brilliant layer is indispensable. To accomplish this endeavor, high-efficiency tank polishing machines have surfaced as essential contraptions. These cutting-edge machines employ cutting-edge technology to optimally clear surface defects and improve a bright sheen on stainless steel tanks.

- Moreover, high-efficiency tank polishing machines are fabricated for optimal effectiveness, boasting durable construction, tough motors, and modern polishing heads that eliminate surface damage.

- Subsequently, fabricators can achieve exceptional results with minimal effort, simplifying their production procedures and delivering high-quality tanks that comply with the stringent specifications of various realms.

Advanced Cylindrical Polishing System for Precision Engineering

The request for exceptional surface level in precision engineering is constantly climbing. To confront these rigorous requirements, a revolutionary cylindrical polishing system has been built. This sophisticated instrument employs cutting-edge methods to reach unparalleled surface evenness. It competently excises imperfections and strengthens the overall capability of cylindrical pieces across a wide range of sectors.

- Advantages include increased output, reduced manufacturing spending, and improved product uniformity.

- The system is constructed to handle a wide range of substances, including metals, ceramics, and plastics.

- Operators can easily customize the polishing parameters to produce the desired coating.

This advanced cylindrical polishing system represents a significant leap forward in precision engineering, permitting manufacturers to produce segments of exceptional worth and operation.

Innovative CNC Polishing Solutions for Complex Shapes

Obtaining a exquisite appearance on intricate elements can be a challenging task. Traditional polishing ways often struggle to yield consistent results on complex shapes, inducing time-consuming loops. However, the advent of intelligent CNC polishing solutions has revolutionized the industry, helping manufacturers to achieve unprecedented scales of accuracy and efficiency.

These advanced systems exploit programmed machining technology to precisely smooth surfaces with minimal operator intervention. Equipped with high-speed spindles and a variety of polishing tools, CNC machines can efficiently handle even the most demanding structures.

In addition, these solutions offer improved control over measures such as pressure, speed, and tool path, assuring consistent results across different materials and complexities.

- Upsides of automated CNC polishing include:

- Enhanced precision and surface texture

- Cut cycle times and production costs

- Improved product consistency and repeatability

- Expanded design flexibility for complex shapes

Robust Tank Polishing Machine for Industrial Applications

For demanding industrial workplaces where capability is vital, a heavy-duty tank polishing machine is an crucial tool. These machines are specifically engineered to handle the stresses of ongoing operation in harsh environments. Equipped with durable construction and high-torque motors, they can effectively wash away rust, paint, and other contaminants from tank surfaces, delivering a smooth and sanitary finish. A variety of implements are available to accommodate different tank sizes and patterns, making them versatile for a wide range of applications.

Smart Control Dished End Polishing System

Our modern Dished End Polisher leverages intuitive Adaptive Control Technology to deliver unparalleled results. This technology continuously analyzes the polishing process in real time, providing optimal surface texture for a wide range of objects. The Adaptive Control Technology accelerates the adjustment of key measures, such as pressure, speed, and oscillation, to achieve repeatable results every time.

- Benefits include:

- Boosted surface finish quality

- Decreased polishing time

- Superior control over the polishing process

- Customizability for a range of materials and applications

Accurate CNC Polishing System for Fine Surface Detailing

A CNC polishing gadget is a effective tool implemented in various areas for producing notable surface finishes. These machines exploit computer numerical control (CNC) technology to meticulously polish surfaces, clearing imperfections and producing a smooth, refined appearance. The heavy-duty design of CNC polishing machines supports for varied output.

- Engineering fields

- Polymers

- Optimizing visual appeal

The digital nature of CNC polishing machines maintains consistent results, curtailing human error and raising efficiency. By leveraging a variety of abrasive materials, these machines can manage a diverse selection of surface models and components.

Specialized Large Cylinder Polishers

Creating and polishing large diameter cylindrical modules often depends on specialized equipment. These machines are engineered to deliver precise parameters on objects with significant girth, using a variety of finishing accessories.

The choice of cylindrical polishing equipment hinges on the specific industry and desired outcome. Some common types include rotary polishers, each offering distinct advantages for refining coatings.

- Fixtures are essential to securely hold large diameter pieces throughout the processing process.

- Adjustments in tool position and feed rate are critical for securing consistent results.

Fast-Track Dished End Polishing Machine for Mass Production

In up-to-date promptly growing manufacturing arena, the drive for efficient high-volume production processes is paramount. To meet this challenge, manufacturers are turning cutting-edge technologies like high-speed dished end polishing machines. These sophisticated systems deliver exceptional precision in a time-sensitive manner, ensuring consistent quality and high surface finishes for a wide range of components.

Designed to handle large production runs with significant speed, these machines make use of advanced polishing techniques to realize flawless finish required for demanding applications. Primary features include high-speed spindles, intelligent control systems, and innovative buffing pads that work in synergy to maximize productivity.

Moreover, these machines often incorporate automation capabilities for increased results and reduced labor costs. This combination of speed, accuracy, and machine control makes high-speed dished end polishing machines a vital asset for manufacturers attempting to elevate their production processes and accommodate the growing requests of the market.

Acute CNC Polishing for Aerospace and Hospital Devices

In the challenging fields of aerospace and medical device fabrication, surface texture is indispensable. CNC polishing delivers a highly careful and secured method to attain the exacting looks required for these critical applications. By utilizing advanced CNC machining technology, manufacturers can create surfaces with exceptional flatness, accuracy, and endurance. This process makes possible the production of components that fulfill stringent protocols for performance, reliability, and trustworthiness.

- preferences requirements demands criteria needs

- As well, CNC polishing boosts the wear resistance and biocompatibility of products used in aerospace and medical devices.

- Consequently, it plays a vital role in extending the lifespan and enhancing the capability of these products.

Customizable Cylindrical Polishing System for Customization

Showcasing a revolutionary approach to cylindrical polishing: the Modular Cylindrical Polishing System. This state-of-the-art system provides unparalleled customization, modifying to your specific preferences. With its interchangeable design, you can smoothly adjust the polishing heads, items, and parameters to obtain the targeted finish for your cylindrical objects.

- conditions needs tank polishing machine expectations

- Merit1

- Benefit2

- Advantage3