Formulating a dependable and steadfast circuitous core equipment (RMU) demands meticulous assessment of numerous variables. The extent and organization of the framework should be tailored to the distinct energy needs of the usage. Additionally, the election of sections such as controls must observe to commercial criteria and harmonize the working current potential of the network. Additionally, ecological settings, encompassing ambient temperature and air moisture, should be acknowledged during the construction phase to confirm optimal output.

- Defense systems are primary in RMU formulation, implementing protocols to block issues and protect staff and tools.

- Repair accessibility should be a objective during the design process, allowing for quick inspection and repair when required.

- Future expansion is another paramount aspect to weigh, validating that the RMU can be flexibly adapted to handle pending voltage necessities.

Optimal Capacitor Bank Choices for Power Factor

Choosing out the optimal storage bank for electrical factor correction calls for a in-depth awareness of the electromechanical setup properties. Key items comprehend the scale of the reactive energy, the voltage capacity, and the signal frequency of the network location. An optimal capacitor assembly increases power quality, decreasing outlays, lowering circuit current, and strengthening the full-scale working quality of the energy network.

- Besides, right storage size assessment mitigates voltage spikes and preserves steady power distribution.

- In addition to technical attributes, ambient factors can also govern charge bank choice.

For optimal maximum gains from power optimization, a trained electrical engineer should carry out a extensive analysis and suggest the most effective capacitor bank configuration.

Evaluating PFC Capacitor Functionality and Durability

Studying the effectiveness of Power Factor Correction (PFC) blocks is essential for maintaining optimal system performance. The examination examines the primary elements that influence PFC capacitor useful life, entailing both efficiency standards and likely failure types. By scrutinizing these components, engineers can optimize system composition, lessen reliability risks, and lastly extend the uptime of PFC blocks.

A detailed analysis should encompass a spectrum of testing methodologies, including both investigative and real-world conditions. This multi-dimensional approach grants a sound understanding of PFC capacitor performance characteristics over their full life span.

- Likewise, the analysis should reveal potential weaknesses in PFC capacitor configuration, allowing for targeted upgrades to increase reliability and lengthen service life.

- As a result, the conclusions gained from this performance and reliability analysis will inform the development of more robust and dependable PFC capacitor solutions, enhancing the overall performance of power electronic systems.

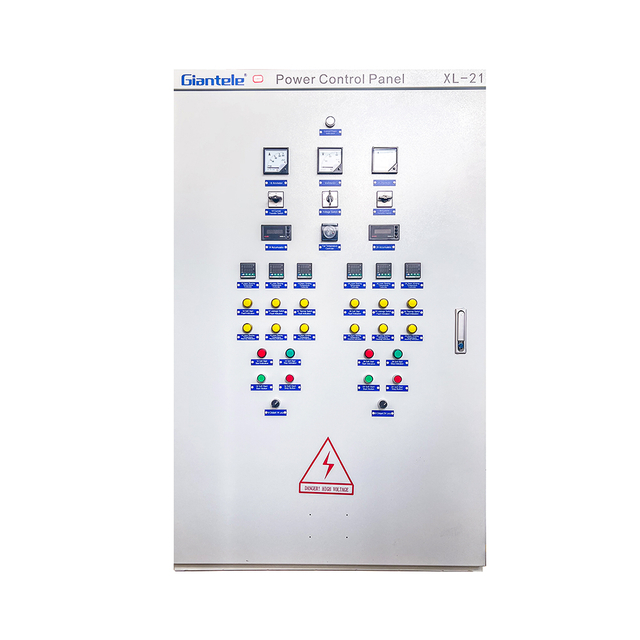

Protected Switchgear Safeguard Configurations

Protected switchgear protection systems are required for shielding electrical equipment and operators from the perils of excessive currents, short circuits, and electrical boosts. These systems typically encompass a group of protective equipment such as circuit breakers, housed within a strong metal cabinet. The cover provides both constructional and warming protection, forbidding damage to the internal parts and cutting down on the exposure of electrical current injury or ignition. Cased switchgear is regularly used in production spheres, energy supply frameworks, and business centers where major levels of soundness and safety are necessary.

- Enclosed switchgear provides several advantages over other types of protection systems.

- The tough design resists harsh environmental conditions.

- The clearly outlined spaces within the cabinet allow for accessible reach and sustenance.

Contrasting Ring Main Units and Distribution Boards

Upon selecting the proper circuit organization for your property, you'll likely run into two fundamental options: ring main units and distribution boards. Despite both offering the important job of supplying electrical flow throughout a establishment, they vary in their configuration and employment.

Ring main units are built as a unified organization that creates a circuit for current to circulate. They usually use multiple channels uniting various nodes within a facility.

Distribution panels, on the other flank, are more versatile in structure. They comprise a succession of disconnect switches that direct individual paths within a structure. Particular circuit breaker can be flipped off exclusively, delivering greater flexibility over energy distribution delivery.

Optimizing Ring Main Unit Formation for Load Balancing

Attaining balanced load balancing within a ring main unit (RMU) setup entails careful planning and strategy. With thoughtfully positioning loads across the RMU's limbs, you can alleviate stress on individual components, boosting system robustness. Adopting monitoring tools and data provides valuable knowledge for systematically changing the RMU configuration to withstand fluctuating demands.

Understanding PFC Capacitor Voltage Ratings

Charge storage units applied in power factor correction (PFC) networks must tolerate the voltage value applied during operation. The voltage measurement of a capacitor declares the maximum magnitude of voltage it can safely handle without deterioration. Operating a PFC capacitor at or over the its rated voltage can lead to grave damage, including electrical disruptions and potential fire hazards. As a result, identifying capacitors with an befitting voltage rating is important for maintaining the robustness of the PFC layout and preventing unplanned consequences. It is necessary to consult the parameters provided by the capacitor producer to calculate the optimal voltage rating required for your specialized PFC exercise.

Metal-Clad Switchgear Examination and Maintenance

Suitable support of metal-cased switchgear is crucial for maintaining the uninterrupted service of your electrical assembly. Ongoing surveys allow you to find potential malfunctions before they give rise to costly downtime. During these inspections, it's mandatory to carefully examine all components, including cable ends, insulators, and operating mechanisms. Monitor for signs of rust, loose terminals, or any other outliers. Take note that fabricator directives should always be followed for specific servicing plans. Proper documentation of all reports is critical for tracking the performance of your switchgear over time. Such records support future maintenance and corrective action.

These Electrical Assemblies Fault Current Handling Capabilities

Orbicular main fixtures are built to handling large fault currents. This ensures the protection of the grid from damage caused by electrical breakdowns. RMUs typically incorporate circuit breakers with authorized fault handling limits to limit fault currents. The selection of the appropriate RMU depends on the calculated fault current levels in the electrical distribution system.

Metal Clad Switchgear Applications in Industrial Facilities

Metal-encased switchgear plays a vital role in affording electrical supply within industrial plants. These tough enclosures preserve critical equipment from stressors while allowing safe and reliable operation. Metal-encased switchgear is particularly fit for applications involving high amperages, lessening the risk of faults. Its modular design allows for easy adaptation as industrial needs evolve. Likewise, metal-clad switchgear often incorporates integrated protection features such as circuit breakers, fuses, and relays, confirming the solidity of the electrical system.

- Typical applications include:

- Electricity supply to machinery

- Motor operation systems

- Illumination and ventilation systems

Progressive Control Techniques for Ring Main Units

RMUs are essential components in power distribution systems, guaranteeing reliable electricity supply to switchgear consumers. To optimize operation and resilience, innovative/state-of-the-art control techniques have emerged. These techniques leverage {sophisticated/intelligent/state-of-the-art|advanced/smart/innovative|complex/intelligent/