Opening

Kinetic separation innovation has arisen as a breakthrough resolution for optimizing rubbish sorting output. This procedure exploits the principle of flight path to separate debris ingredients based on their heaviness. By sending refuse into a compartment, ballistic separation can effectively separate various sections of junk, covering plastics, metals, and biological materials. This efficient approach to scrap coordination can notably boost recycling rates and lessen landfill bulk.

Revolutionary Material Reclamation: The Power of Dynamic Splitters

Impact profilers are transforming the marketplace of material recapture. These state-of-the-art devices use high-velocity air streams to arrange items with impressive accuracy. Unlike conventional techniques, ballistic separators reliably handle a comprehensive range of items, from plastics and metals to glass and organic waste. This elasticity makes them ideal for both massive recycling sites and smaller-scale operations.

The inherent efficiency of ballistic separators grants a significantly enhanced recovery rate compared to conventional techniques. Furthermore, their compressed design provides for integration into existing recycling setups with negligible disruption. As the demand for sustainable operations aims to expand, ballistic separators are on track to play an progressively fundamental role in crafting a circular economy.

- Merits of Ballistic Separators:

- Advanced recovery rates

- Streamlined material separation

- Multifunctionality for varied materials

- Decreased operational costs

- Ecological impact reduction

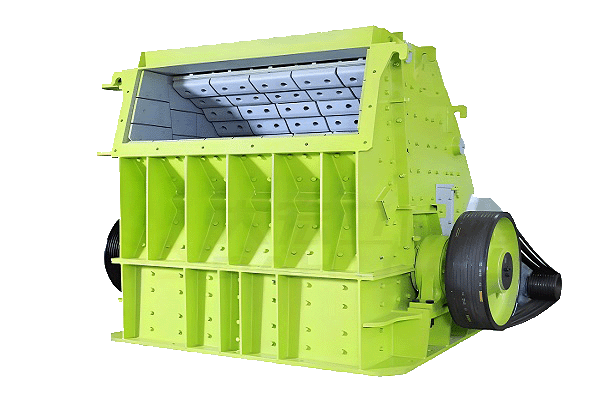

Maximizing Metal Extraction: High-Performance Metal Shredders in Action

The scrap extraction industry is continually seeking novel ways to boost efficiency and reduce natural impact. High-performance metal shredders have developed as a essential fix, delivering unparalleled capabilities for processing abundant volumes of metals. These advanced machines leverage top-tier technology to disassemble discarded materials, distinguishing valuable metals from contaminants with exceptional accuracy.

- Likewise, high-performance metal shredders are known for their durability and endurance, ensuring consistent performance even under demanding situations.

- Consequently, these machines contribute to the environment protection of metal extraction by minimizing waste and amplifying resource utilization.

The embracing of high-performance metal shredders is advancing the industry, spurring advancements in metal recycling and supporting a more sustainable future.

Utilizing a Ballistic Separator for Streamlined Recycling

Developments in recycling technique are fundamental to restrain the green effect of waste. A progressive remedy gaining traction is the ballistic separator. This instrument employs centrifugal force to competently sort recyclable objects based on their weight. By organizing materials into discrete streams, the ballistic separator optimizes the recycling practice, leading to improved recovery rates and a wider range of recyclable components. This milestone holds immense capacity for changing recycling practices and enabling a planet-friendly future.

Smart Waste Separation: Applying AI to Ballistic Separation

The future of waste management is advancing rapidly, driven by the growing need to cut environmental impact. Pioneering technologies are being deployed to boost recycling processes and create a more sustainable future. One such breakthrough is automated waste sorting, which capitalizes on the power of ballistic separators and artificial intelligence (AI) to sort waste components with unprecedented correctness.

Ballistic separators behave by using high-speed air currents to launch different varieties of waste based on their size, shape, and density. This early stage of separation diminishes the complexity of the sorting system for AI algorithms.

Modern AI models can then decipher images and data from sensors to discern specific materials with impressive accuracy. This synergy of ballistic separation and AI enables a notably efficient and robotic waste sorting system.

Modernizing Waste Management: A Comprehensive Guide to Waste Sorting Machines

Waste sorting is a critical step in competent waste management. Manual sorting can be lengthy and faulty, leading to contamination and elevated costs. To address these challenges, cutting-edge waste sorting machines have emerged as a high-performance solution. These machines leverage cutting-edge technology to rapidly sort various waste materials into designated categories.

There are countless types of waste sorting machines available, each designed for targeted applications. Some common types include magnetic sorters, which rely on photoelectric sensors to sort different materials. In addition, robotic arms and conveyor belts can be incorporated to operate waste with sharpness. By streamlining the sorting process, these machines markedly improve efficiency and reduce manual labor requirements.

- Merits of using waste sorting machines include:

- Upgraded efficiency in sorting waste materials

- Reduced labor costs and staff effort

- Raised accuracy in separating recyclable materials from non-recyclable waste

- Reduction of contamination in recycling streams, leading to enhanced quality recycled products

- Ecological benefits through increased recycling rates and reduced landfill waste

Recycling Innovations

Classic recycling methods have long been the standard for separating and processing recyclable components. These approaches often rely on manual sorting by humans, which can be slow and prone to mistakes. However, recent advancements in technology have led to the emergence of advanced recycling methods, such as ballistic separation.

Ballistic separation employs the energy of impact to divide different materials based on their size, weight, and shape. This high-speed method can smoothly handle large volumes of mixed recyclables, reducing manual labor and enhancing the accuracy of sorting.

Compared to traditional methods, ballistic separation offers several advantages. It is a much more systematized process, requiring less human intervention and minimizing the risk of contamination. Additionally, it can handle a wider variety of materials, featuring plastics, metals, glass, and paper. This increased efficiency and flexibility make ballistic separation a useful solution for modern recycling operations.

Exploring A Ballistic Separator for Municipal Solid Waste

This assessment scrutinizes the integration of a ballistic separator in a local solid waste management facility. The focus of this project was to enhance the output of waste distribution. The study assesses the performance aspects of the separator, including its design, feeding mechanism, and sorting system.

Furthermore, the study considers the outcome of the ballistic separator on material flow quality.

- Data collected from the process observation show the effectiveness of the implemented solution.

- Problems faced during the execution process are also examined.

Advice for future optimizations based on the analysis are presented.

Enhancing Material Recovery Through Shredding and Separation Processes

In the realm of waste management, productively recovering valuable materials is essential. Shredding and separation operations play a key role in achieving this goal. By actively reducing materials to smaller pieces, shredding facilitates the subsequent separation stages. Advanced separation technologies, such as magnets, screens, and air classifiers, can then discriminate wide-ranging material types with high exactness. This multi-stage approach facilitates a higher rate of material recovery, decreasing landfill waste and fostering a circular economy.

Choosing a Waste Sorting Machine: Key Considerations

Waste sorting tools are required for competently managing waste and promoting reuse. When choosing a waste sorting machine, it is imperative to consider several elements to ensure it meets your specific needs.

First, determine the type of waste you will be organizing. Different machines are optimized for various types of waste, such as plastics, paper, metals, and organic materials. Next, evaluate the volume of waste you generate. This will influence the load of the machine you require. A enhanced machine is necessary for high-volume waste streams.

Also, reckon with the space available at your installation. Waste sorting machines come in various sizes, so ensure there is sufficient room to embed the machine and allow for smooth operation. Another important item is the degree of automation you require. Computerized machines offer varying degrees of labor input.

Finally, review the continuity associated with different machines. Some machines may need more frequent checks than others.

Increasing Landfill Diversion Rates with Advanced Separation Technologies

Landfills are a considerable source of environmental contamination. To alleviate this matter, many communities are vigorously engaging in ways to amplify landfill diversion rates. Advanced separation technologies offer a potent solution by efficiently sorting recyclable items from waste streams. These innovative technologies leverage sensors and next-gen algorithms to classify various materials. This produces to a boosted recovery rate of recyclable items, as a result cutting down the amount of waste sent to landfills.

The deployment of these advanced separation technologies can bring many benefits. Primarily, it preserves natural resources by reclaiming valuable materials. Secondly, it lowers greenhouse gas emissions associated with waste disposal and the assembly of new materials from raw resources.

ballistic separator Ending